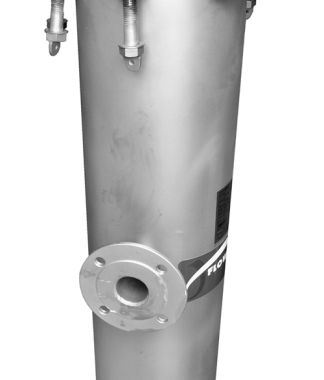

Flowrite “TB” Series

Flowrite “TB” Series Tank breather filters are fabricated from 304-Stainless Steel. They are designed for a maximum operating pressure of 100 kPa at80ºC, depending on cartridges fitted. The “TB” Series housings feature Flowrite’s well proven centre post and nut design. Cartridges are located by their own end seals and a securing plate to which is attached a perforated stainless steel shield which allows free passage for the entering and exiting air during tank emptying and filling cycles.

The cartridges have double ”O” rings which give a perfect seal between cartridges and housing, thus eliminating any possibility of bypass. The practical and sturdy design of these housings allows quick and convenient cartridge change out of the 9¾” modular length filter cartridges.

Flowrite “TB” Series filter housings are available in one, two, three & four cartridge configurations to minimize pressure drop, and thus protect the tank from differential pressures while emptying or filling. The inlet port can be threaded or flanged to your specifications, and the unit is supplied in electro polished finish suitable for most semi and non-sanitary applications.

The housing should be used in conjunction with hydrophobic cartridges with a micron rating to your specification, which are also available from Flowrite

FEATURES & BENEFITS

Electro-polished, stainless steel construction

Suitable for most semi- & non-sanitary applications

Centre post & nut design

Quick, easy and convenient access to the filter cartridges

Integral locators & double “O” rings

Positive cartridge location and sealing eliminates bypass

Easy mounting

Flanged or threaded bottom inlet makes for direct, convenient, tank-top mounting

2-Piece construction

Easy to clean and versatile design

Flowrite “TB” Tank Breather filters are custom designed and made to order. Thus, when ordering or enquiring, please specify:

- The tank volume

- The liquid contained in the tank

- The inflow and outflow rates

- The operating temperature

- The degree of filtration required

- Suitable materials of construction

Once this information is available, a detailed, no obligation quotation for suitable housings and filter cartridges can be provided.