Prius P MF

EMEC’s PRIUS P dosing pump has 10 working modes:

- constant

- ppm,

- %,

- mlq,

- pause-work,

- weekly,

- pulse,

- mA,

- Volt

- and Batch

EMEC’s Prius also comes with the ability to measure level control, alarms and stand-by, the EMEC Prius comes in two mounting positions standard or rotated mounting.

Our piston can be supplied in either ceramic or SS plunger, aluminium enclosure, flow regulation and double ball check valve.

A Multifunction motor-driven pump brings a unique level of management thanks to LCD display and encoder electronic controller that ensure the highest accuracy in dosage setting.

The Prius is a Motor-driven plunger dosing pump, mechanical actuated, PRIUS combines efficiency and chemical resistance to a wide capacity range for an extensive number of applications.

• Multifunction plunger pump with inverter for low power ratings

• Working mode: Constant, ppm, %, mlq, pause-work, weekly, mA, Volt and Batch

• Level control

• Alarms

• Stand-by

• Double position of the electronic unit (standard or rotated mounting)

• Ceramic or Stainless Steel plunger

• Aluminium enclosure

• Flow regulation

• Double ball check valve

• Tropicalized three-phase motors

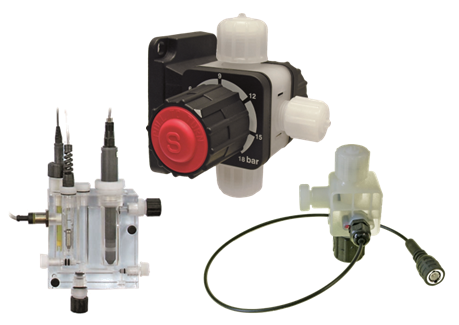

LOTUS – CHLORINE DIOXIDE GENERATOR

WITH PROBE FOR MEASUREMENT

LOTUS MINI is all-round solution for all your need of CHLORINE DIOXIDE GENERATOR water disinfection. LOTUS MINI with probe measure system produces, doses and controls chlorine dioxide for water disinfection. It is equipped with ClO2 probe (SCL2 or SCL17) or an mV probe (ERH), a probe holder and a filter.

Chlorine dioxide is produced from diluted base chemicals: acid-chlorite process by hydrochloric acid (HCl 9%) and sodium chlorite (NaClO2 7,5%). Chlorine dioxide produced by LOTUS MINI is set to be proportional to the circulating water flow or based on a set-point – it is then dosed into the water flow. There is no storage of chlorine dioxide hence no chlorine dioxide gas or concentrated solutions exist outside of the process application.

LOTUS MINI chlorine-dioxide-gererator with probe measure is designed to produce chlorine dioxide in a reaction chamber. Multi-function valves on the injection points ensure the security of the reaction chamber.

The base chemicals are stored in tanks and fed into the reaction chamber through suction lances. Integrated level switches automatically stop the pumps when the tanks are empty.

GAS SENSOR OPTION

This model of LOTUS MINI is equipped with gas sensor detection.

FEATURES

- PERMANENT DATA STORAGE (WITHOUT BATTERY) with system log on display

- Stand-by input

- 3 flow sensors (mod. SEFL) input

- Real time production data

- Multifunction valve (MFKT/V)

- IP65 protection (NEMA4x) of LOTUS control instrument

- Working temperature: 0-45°C (32-110°F)

- PVC reaction chamber

- Instantaneous ClO2 production

- ClO2 dosing in PROPORTIONAL mode

- Pumps and SEFL flow sensors monitoring

- Service due data

- Water meter input

- Flow control input (flow alarm)

- Tank level controls (level alarms)

- LOTUS control instrument

- Pump for diluition water (grey)

- mA output

- ClO2 probe reading (LOTUS MINI SCL2 – LOTUS MINI SCL17)

- Temperature probe reading (probe and accessories not included)

- mV probe reading (LOTUS MINI ERH)

- ASA (Acrylonitrile Styrene Acrylate) enclosure

MODELS

LOTUS MINI 8 WITH PROBE MEASURE

- HOUR CAPACITY

- 8 g/h

- PRESSURE

- 8 bar

- CHEMICAL CONSUMPTION

- HCl 0.2 l/h

- NaClO2 0.2 l/h

- CONCENTRATION

- 2 g/l

LOTUS MINI 20 WITH PROBE MEASURE

- HOUR CAPACITY

- 20 g/h

- PRESSURE

- 8 bar

- CHEMICAL CONSUMPTION

- HCl 0.5 l/h

- NaClO2 0.5 l/h

- CONCENTRATION

- 2 g/l

COMMUNICATION

- ERMES

- MODBUS

CONFIGURATION

BASIC

- RS485 output to link other EMEC instruments

WIFI

- RS485 output to link other EMEC instruments

- Web ERMES remote control (PC, smartphone or tablet)

- Alarm messages via email

ADVANCED USB

- RS485 output to link other EMEC instruments

- Data Log on USB device

ETHERNET

- RS485 output to link other EMEC instruments

- Web ERMES remote control (PC, smartphone or tablet)

- Alarm messages via email

2G – 3G

- RS485 output to link other EMEC instruments

- Web ERMES remote control (PC, smartphone or tablet)

- Alarm messages via email

- Alarm messages via SMS

MODBUS

- Connection to other PLC instruments via RS485 or TCP/IP for reading and modifying parameters

CENTURIO TOWER

CENTURIO TOWER is the control instrument in cooling tower water

treatment, with the ease and safety of operation you need and with the stylish box designed by Giugiaro Design.

CENTURIO is equipped with a Linux operating system, a high performance

ARM A5 microprocessor, a large, touchscreen, colour display, in order to give you total and simultaneous control.

- Parameters: conductivity, chlorine, pH, ORP, tracers, inductive conductivity, mA Input.

- 5 channels to combine

- Real-time graphs

- Permanent data storage with system log

- USB Download

- Data import/export (backup & restore) via USB port to other CENTURIO.

- Internet connection (WIFI, 3G or LAN), configuration and control by ERMES web app using PC, smartphone or tablet with any browser.

- MODBUS serial communication to be connected to other devices on RS485 networks and TCP/IP MODBUS.

The “CENTURIO Tower” is a fully featured cooling towers controller with two-way biocide options and inhibitor / bleed control with 5 channels.

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or rely solely on air to cool the working fluid to near the dry-bulb air temperature.

Common applications include cooling the circulating water used in oil refineries, chemical plants, power plants and building cooling.

All information is provided through a large COLOUR LCD display (480×272). “CENTURIO Tower” is housed in an IP65 plastic box.

Prius P MF

EMEC’s PRIUS P dosing pump has 10 working modes:

- constant

- ppm,

- %,

- mlq,

- pause-work,

- weekly,

- pulse,

- mA,

- Volt

- and Batch

EMEC’s Prius also comes with the ability to measure level control, alarms and stand-by, the EMEC Prius comes in two mounting positions standard or rotated mounting.

Our piston can be supplied in either ceramic or SS plunger, aluminium enclosure, flow regulation and double ball check valve.

A Multifunction motor-driven pump brings a unique level of management thanks to LCD display and encoder electronic controller that ensure the highest accuracy in dosage setting.

The Prius is a Motor-driven plunger dosing pump, mechanical actuated, PRIUS combines efficiency and chemical resistance to a wide capacity range for an extensive number of applications.

• Multifunction plunger pump with inverter for low power ratings

• Working mode: Constant, ppm, %, mlq, pause-work, weekly, mA, Volt and Batch

• Level control

• Alarms

• Stand-by

• Double position of the electronic unit (standard or rotated mounting)

• Ceramic or Stainless Steel plunger

• Aluminium enclosure

• Flow regulation

• Double ball check valve

• Tropicalized three-phase motors

LOTUS – CHLORINE DIOXIDE GENERATOR

WITH PROBE FOR MEASUREMENT

LOTUS MINI is all-round solution for all your need of CHLORINE DIOXIDE GENERATOR water disinfection. LOTUS MINI with probe measure system produces, doses and controls chlorine dioxide for water disinfection. It is equipped with ClO2 probe (SCL2 or SCL17) or an mV probe (ERH), a probe holder and a filter.

Chlorine dioxide is produced from diluted base chemicals: acid-chlorite process by hydrochloric acid (HCl 9%) and sodium chlorite (NaClO2 7,5%). Chlorine dioxide produced by LOTUS MINI is set to be proportional to the circulating water flow or based on a set-point – it is then dosed into the water flow. There is no storage of chlorine dioxide hence no chlorine dioxide gas or concentrated solutions exist outside of the process application.

LOTUS MINI chlorine-dioxide-gererator with probe measure is designed to produce chlorine dioxide in a reaction chamber. Multi-function valves on the injection points ensure the security of the reaction chamber.

The base chemicals are stored in tanks and fed into the reaction chamber through suction lances. Integrated level switches automatically stop the pumps when the tanks are empty.

GAS SENSOR OPTION

This model of LOTUS MINI is equipped with gas sensor detection.

FEATURES

- PERMANENT DATA STORAGE (WITHOUT BATTERY) with system log on display

- Stand-by input

- 3 flow sensors (mod. SEFL) input

- Real time production data

- Multifunction valve (MFKT/V)

- IP65 protection (NEMA4x) of LOTUS control instrument

- Working temperature: 0-45°C (32-110°F)

- PVC reaction chamber

- Instantaneous ClO2 production

- ClO2 dosing in PROPORTIONAL mode

- Pumps and SEFL flow sensors monitoring

- Service due data

- Water meter input

- Flow control input (flow alarm)

- Tank level controls (level alarms)

- LOTUS control instrument

- Pump for diluition water (grey)

- mA output

- ClO2 probe reading (LOTUS MINI SCL2 – LOTUS MINI SCL17)

- Temperature probe reading (probe and accessories not included)

- mV probe reading (LOTUS MINI ERH)

- ASA (Acrylonitrile Styrene Acrylate) enclosure

MODELS

LOTUS MINI 8 WITH PROBE MEASURE

- HOUR CAPACITY

- 8 g/h

- PRESSURE

- 8 bar

- CHEMICAL CONSUMPTION

- HCl 0.2 l/h

- NaClO2 0.2 l/h

- CONCENTRATION

- 2 g/l

LOTUS MINI 20 WITH PROBE MEASURE

- HOUR CAPACITY

- 20 g/h

- PRESSURE

- 8 bar

- CHEMICAL CONSUMPTION

- HCl 0.5 l/h

- NaClO2 0.5 l/h

- CONCENTRATION

- 2 g/l

COMMUNICATION

- ERMES

- MODBUS

CONFIGURATION

BASIC

- RS485 output to link other EMEC instruments

WIFI

- RS485 output to link other EMEC instruments

- Web ERMES remote control (PC, smartphone or tablet)

- Alarm messages via email

ADVANCED USB

- RS485 output to link other EMEC instruments

- Data Log on USB device

ETHERNET

- RS485 output to link other EMEC instruments

- Web ERMES remote control (PC, smartphone or tablet)

- Alarm messages via email

2G – 3G

- RS485 output to link other EMEC instruments

- Web ERMES remote control (PC, smartphone or tablet)

- Alarm messages via email

- Alarm messages via SMS

MODBUS

- Connection to other PLC instruments via RS485 or TCP/IP for reading and modifying parameters

CENTURIO TOWER

CENTURIO TOWER is the control instrument in cooling tower water

treatment, with the ease and safety of operation you need and with the stylish box designed by Giugiaro Design.

CENTURIO is equipped with a Linux operating system, a high performance

ARM A5 microprocessor, a large, touchscreen, colour display, in order to give you total and simultaneous control.

- Parameters: conductivity, chlorine, pH, ORP, tracers, inductive conductivity, mA Input.

- 5 channels to combine

- Real-time graphs

- Permanent data storage with system log

- USB Download

- Data import/export (backup & restore) via USB port to other CENTURIO.

- Internet connection (WIFI, 3G or LAN), configuration and control by ERMES web app using PC, smartphone or tablet with any browser.

- MODBUS serial communication to be connected to other devices on RS485 networks and TCP/IP MODBUS.

The “CENTURIO Tower” is a fully featured cooling towers controller with two-way biocide options and inhibitor / bleed control with 5 channels.

Cooling towers are heat removal devices used to transfer process waste heat to the atmosphere. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet-bulb air temperature or rely solely on air to cool the working fluid to near the dry-bulb air temperature.

Common applications include cooling the circulating water used in oil refineries, chemical plants, power plants and building cooling.

All information is provided through a large COLOUR LCD display (480×272). “CENTURIO Tower” is housed in an IP65 plastic box.

PRISMA Dosing Pump

The PRISMA dosing pumps: the incomparable accuracy of the stepper motor – EMEC.

EMEC is proud to introduce the new stepper motor-driven dosing pump- PRISMA, the best solution for high-accuracy metering and extreme reliability.

Thanks to the new stepper motor and to the Multi-Function software, the PRISMA dosing pump offers complete control over dosing speeds. Working modes as well as great flexibility and repeatability, meeting even particularly complex application needs.

The PRISMA is also equipped with Level control, Alarms and Stand-by, while available working modes include Constant, Constant with external input, ppm, %, mlq, Pause-work, Weekly, mA, Pulse, Volt, external Batch and manual Batch.

The PRISMA dosing pumps feature the encoder control knob for quick browsing through the configuration menus. A large display screen allows for easy control and to regulate the working parameters. By changing background colors the PRISMA back-light display is capable of signaling different working status: pump running (green); stand-by (white); warning condition (yellow); alarm condition (red).

[YouTube_WD id=”4″]TURNDOWN

The PRISMA stepper motor-driven pumps give you the most accurate control over the stroke speed, providing an outstanding turn-down ratio of up to 4800:1.

It means that the PRISMA, through its digital multi-function control, can split up the dosing process into a maximum of 4800 steps. This is in order to offer the most homogeneous and precise distribution of the product to dose according to the required application.

SLOW MODE

The extreme versatility of the PRISMA dosing pump is also due to Slow Mode function. With Slow Mode enabled you can reduce the suction speed to 75, 50 or 25% of the normal speed, making easier, more reliable and extremely accurate the priming and the dosing, even when you have to handle particularly viscous liquids.

CAPACITY RANGE

The PRISMA stepper motor-driven pumps are available with dosing capacity of 5, 13, 28 and 80 l/h at a working pressure of 20, 10, 5 and 2 bar, respectively.

TYPE D – Diaphragm Dosing Pump

D- Type Diaphragm Dosing Pump

D” type mechanical diaphragm metering pumps are suitable for use when the liquid to dose contains small suspended solids and when high pressure is not required.

The gearbox is a standard wormwheel reduction system coupled with a vertical mounted B14 shaped electric motor in accordance with UNEL-MEC specification. The mechanism for variation of the stroke length is a positive stroke spring return operated by an eccentric.

Stroke adjustment can be done manually, electrically (4-20mA; Profibus) and pneumatically. Different multiple head units are available on request. All the series can be ATEX certified.

Diaphragm pumps are suitable for use when:

- The liquid dosed contains small amounts of suspended solids

- The liquid dosed is abrasive

- High pressure is not required

- Flow rates – min 4l/h; max 1400l/h

- Pressure ranges from 3 to 10 bar

- Available in 220V, 380V & 525V – IP55

- Standard wet-end executions in PVC and 316 stainless steel.

- Diaphragm in PTFE

- Multi-headed pumps also available on request.

Stroke adjustment can be carried out:

- Manual: by means of a linear micrometre screw from 0-100%

- Electrical: by means of a motor servo controller with a 4-20mA signal

- Pneumatic: by means of a pneumatic servo controller.

EMEC – SPARES AND ACCESSORIES

At Germ Africa we Stock a range of spares available making repair and maintenance easy.

These include :

- injection valves

- foot valves

- suction and delivery valves

- pump head, solenoids

- diaphragms etc.

Accessories include:

- Flow sensors

- Multi function valves

- Proximity switches

- Pulsation Dampeners

- Level probes

- Probe holders

DIN DIGITIAL SERIES

DIN DIGITAL

The DIN Digital Series are compact, versatile and user-friendly DIN bar mounting instruments to control and measure pH, Redox (ORP), Chlorine, Conductivity, Ozone and Dissolved Oxygen. They provide reliable and accurate measurements using a digital keyboard and LCD backlight display.

- Microprocessor based technology controller which is mounted on din rail.

- The controller has two ON/OFF outputs for the setpoints and one 4÷20 mA output for the chart recorder. This current output can be ordered with galvanic isolation to be connected to a PC or a PLC.

- Controllers are available for the following applications: pH, ORP, Conductivity, Temperature, Turbidity and Chlorine (Free or Total Chlorine)

SWIMMING POOL PUMPS – WD – Series

Swimming Pool Pump

WDPHRH system integrates a control instrument and two proportional metering pumps and is the perfect solution for specific dosage need like that of swimming pools sector.

It is equipped with backlit LCD display, encoder control, PVDF pump heads and liquid ends, stand-by, flow sensor input, programmable delay at dosing startup, pH priority dosage, service menu with probe reading value, probe check-up and alarms.

WD –Series

- WDPHRH – Swimming pool controller with 2 metering pumps for acid (pH) and disinfectant (ORP).

- Ranges: 0-14 pH and 0-1000 mV.

- Instrument control by a rotation “Encoder”.

- Alarm output, max dosing time alarm, probe check-up, pH priority dosage.

- Pump heads and liquid ends in PVDF.

- Flow: 3 bar-10 l/H

- WDPHCL – Swimming pool controller with 2 metering pumps for acid (pH) and chlorine (Cl).

- Ranges: 0-14 pH and 0-10 mg/l Cl2.

- Instrument control by a rotation “Encoder”.

- Alarm output, max dosing time alarm, probe check-up, pH priority dosage.

- Pump heads and liquid ends in PVDF.

- Flow: 3 bar-10 l/h.

V Series: Analogue Wall Mounted Pumps

V-Series Analogue metering pumps are manufactured in moulded glass filled and polypropylene housing to ensure protection against aggressive chemicals and tough environment.

VCO

Constant pump with stroke speed (frequency) adjustment and divider mode by 10 times the pumps capacity.

VCL

Constant pump with level control, stoke speed (frequency) adjustment and divider mode by 10 times the pumps capacity.

T Series – Wall Mounted Pumps

T series Metering Pumps – Wall Mounted Pumps

T-Series Digital metering pumps are manufactured in moulded glass filled and Polypropylene housing, thus ensuring protection against aggressive chemicals and tough environment.

TMS MF

Solenoid-driven metering pump, the TMS MF is the perfect solution for high-dosage need.

Wall mounted, it is equipped with back lit LCD display and microprocessor technology. All liquid ends are in PVDF, but pump head and accessories in PP and hose in PE are available on request.

Pump head is available with manual or self venting.

TMS MF, with constant/proportional dosing system, has level control, flow sensor input, stand-by input, alarm output and the following functions: multifunction, automatic repriming, strokes recovery system, upkeep dosing mode in plant shutdown situation and work-pause mode.

TMS PH

Proportional pump driven by an internal pH meter (0-14pH) and level control.

TMS RH

Proportional pump driven by an internal ORP meter (0-1000mV) and level control.